CO2 Removal & Storage with Microalgae

We permanently remove CO2 from the atmosphere by growing and burying microalgae.

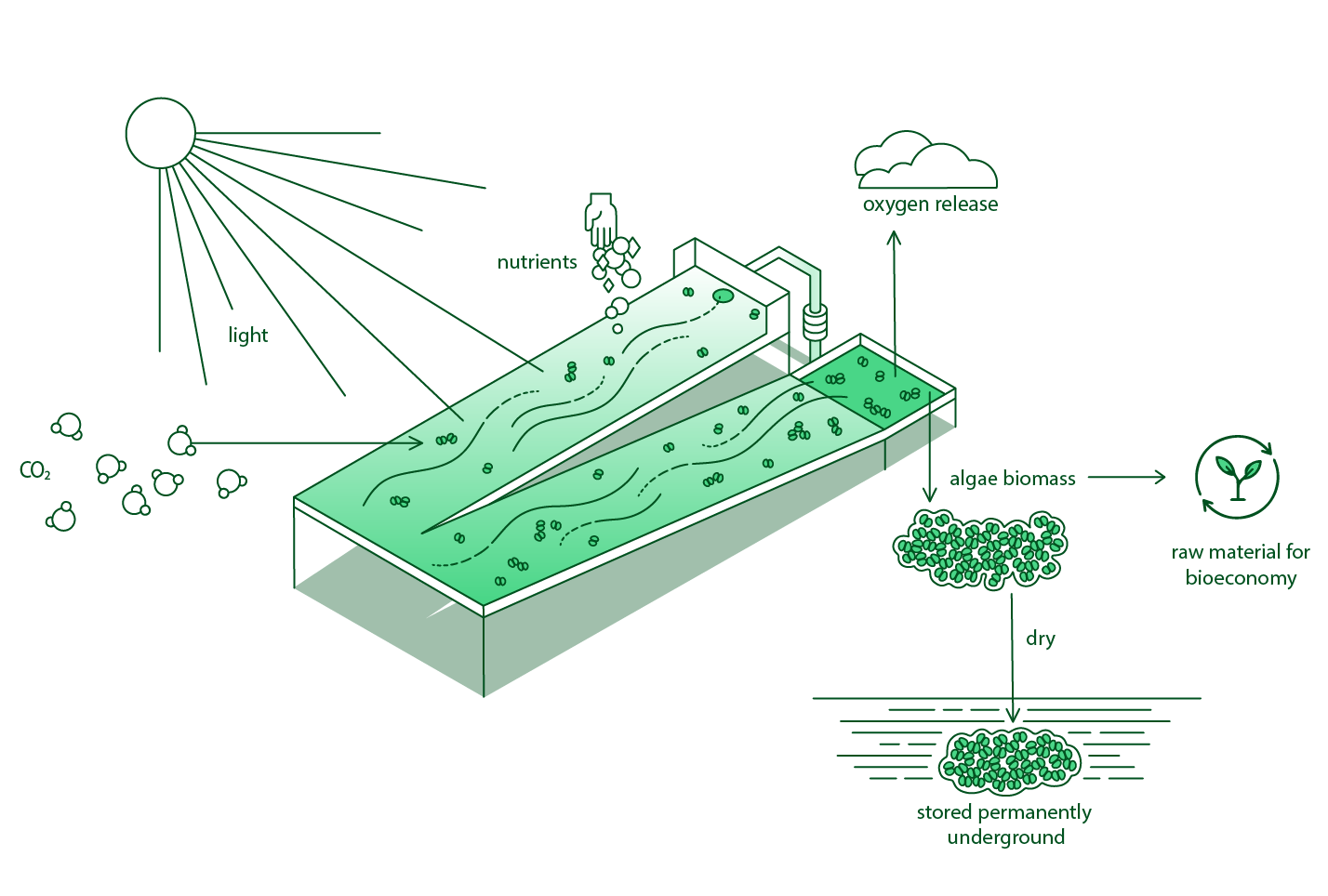

Biomass Carbon Removal and Storage (BiCRS) combines photosynthesis with technology. Our outdoor photobioreactors create ideal conditions for the rapid growth of microalgae biomass in water using sunlight. Through photosynthesis, the algae bind CO2 from the atmosphere as a natural process. That’s why our BiCRS approach is energy- and cost-efficient.

Our Process

Photosynthesis in algae has been optimized over millions of years of evolution. We adapt this already highly efficient process and enhance it with technology for our approach to biomass carbon removal and storage (BiCRS). It involves three steps:

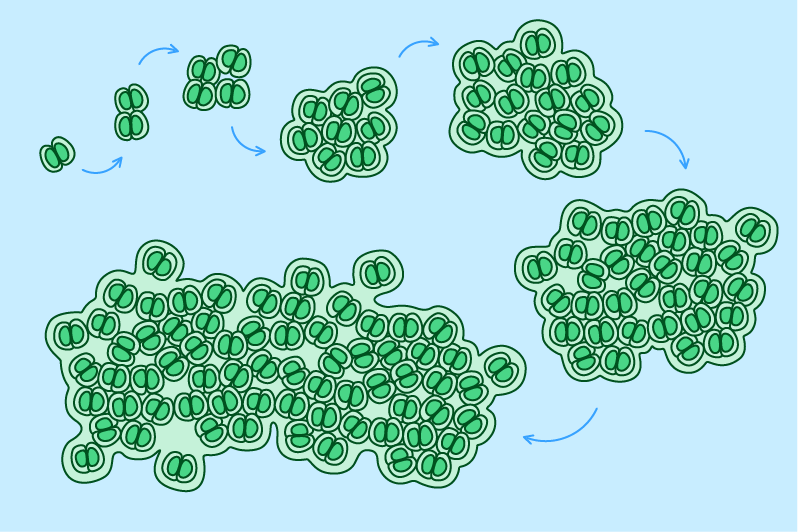

1. Growth

In our photobioreactors, algae grow by cell division. They thrive in natural light and are supplied with nutrients and CO2 from the atmosphere. During photosynthesis, the algae bind CO2 and the produced oxygen is released into the atmosphere.

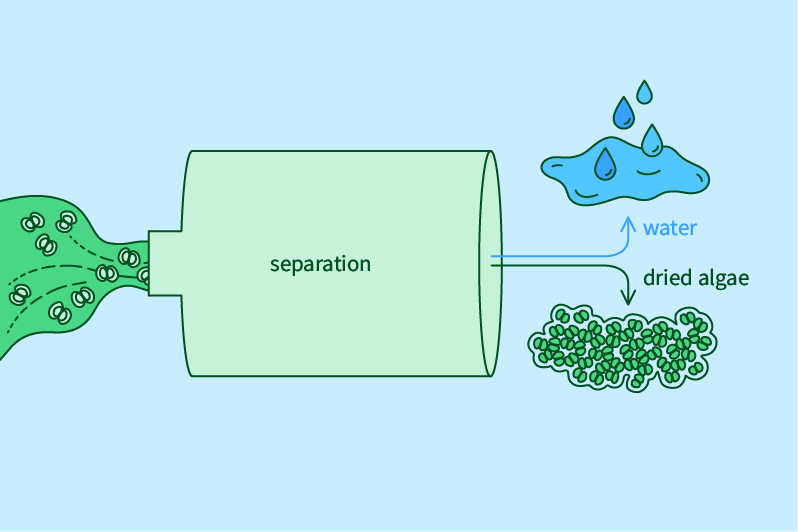

2. Harvesting & Drying

As soon as the algae have reached a certain density, harvesting begins. Part of the biomass is continuously filtered from the water and dried. The dried biomass consists of more than 50% carbon.

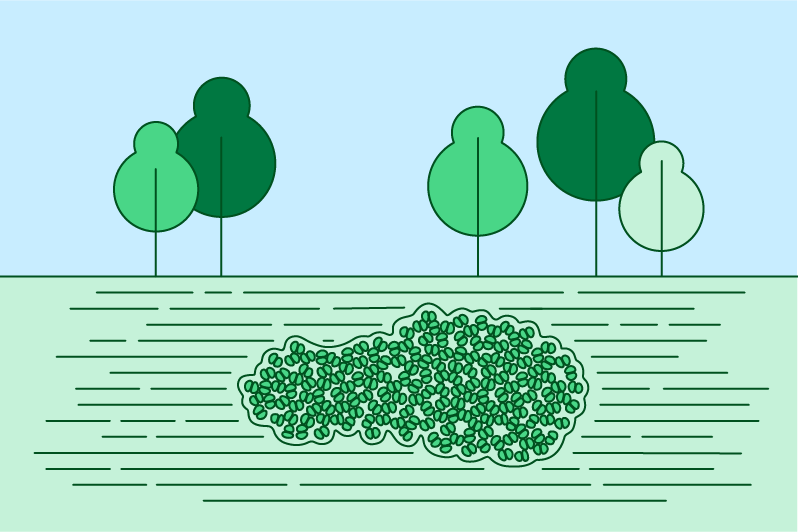

3. Storage

The carbon-rich biomass is stored underground for the long term, e.g. in disused gravel pits or underground mines. Overall, the process has a negative CO2 balance and is therefore considered a negative emission technology.

Benefits of our Carbon Removal Solution

MEASURABLE

We weigh the biomass and measure its carbon content before we bury it. This allows us to determine exactly how much CO2 has been removed from the atmosphere. With 1 kg of algae biomass about 1.8 kg of CO2 can be removed.

PERMANENT

The composition of the dried biomass and suitable storage conditions, such as pH value and water content, ensure that it remains stable for over 1000 years. This means that the removed carbon is permanently locked away.

ENERGY-EFFICIENT

Sunlight is the main energy source in our approach. Therefore, we only need about 1.5 kWh of technical energy to bind 1 kg of CO2. We avoid transport or keep distances short by operating our bioreactors in the immediate area of the storage site.

ADDITIONAL

Our process verifiably removes additional CO2 from the atmosphere on your behalf. This avoids double counting of our CO2 removal certificates.

VERIFIABLE

We attach great importance to a high standard of monitoring, reporting and verification (MRV) to ensure transparency and verifiability of our process.

SCALABLE

Our photobioreactors enable the highly efficient production of biomass for CO2 sequestration. They are modular, scalable and plug & play ready for installation.

What are Negative Emission Technologies?

Negative emission technologies (NET) include technological approaches and strategies to remove carbon dioxide (CO2) and other greenhouse gases from the atmosphere. By definition, more CO2 is removed than is emitted by the application of the technology. NETs therefore reduce the overall concentration of CO2 in the atmosphere and its impact on global warming.

The negative emission technology developed by Arrhenius is based on microalgae.

Why we need negative emissions

Negative emissions are not a substitute for drastically reducing greenhouse gas emissions! Avoiding CO2 at its source remains the most effective and urgent strategy to address climate change.

The transition to renewable energy and other non-fossil resources is progressing, but it will take time. Some emissions may not be reduced fast enough. In addition, there will always be CO2 emissions that are hard-to-abate or unavoidable, such as those from agriculture or waste incineration. These emissions can be tackled with negative emission technologies.

Biomass for Bioeconomy

Arrhenius’ photobioreactors provide precise control over operating parameters, ensuring fast and highly efficient biomass production. Our microalgal biomass is tailored for various applications within the bioeconomy.

Replacement of fossil materials

Microalgal biomass can replace fossil raw materials in several industries. This improves the carbon balance by eliminating unnecessary emissions and reducing the overall CO2 footprint. Possible applications include the sustainable production of:

- Industrial goods (e.g. dyes, cosmetics or bioplastics)

- Fuels (e.g. biodiesel or bioethanol)

- Agriculture fertilizer (e.g. biofertilizer)

- Platform chemicals (e.g. ethanol, glycerin)

Avoid long distance transportation

In the food and animal feed industry, microalgae serve as a sustainable source of protein. For example, they can replace soy in animal feed. Unlike soy, which is often transported over long distances, microalgae can be produced locally with high efficiency. This further reduces the environmental impact.

Our Services

Arrhenius offers various services related to bioreactor design and microalgae production, as well as customized analyses:

Consultancy and Feasibility Studies

-Conceptual design & implementation of feasibility studies

-Life Cycle (Impact) Analyses (LC(I)A)

-Techno-Economic Analyses (TEA)

-Utility Analyses (UA)

-Energy, mass and material balances

-Ecological and economic calculations

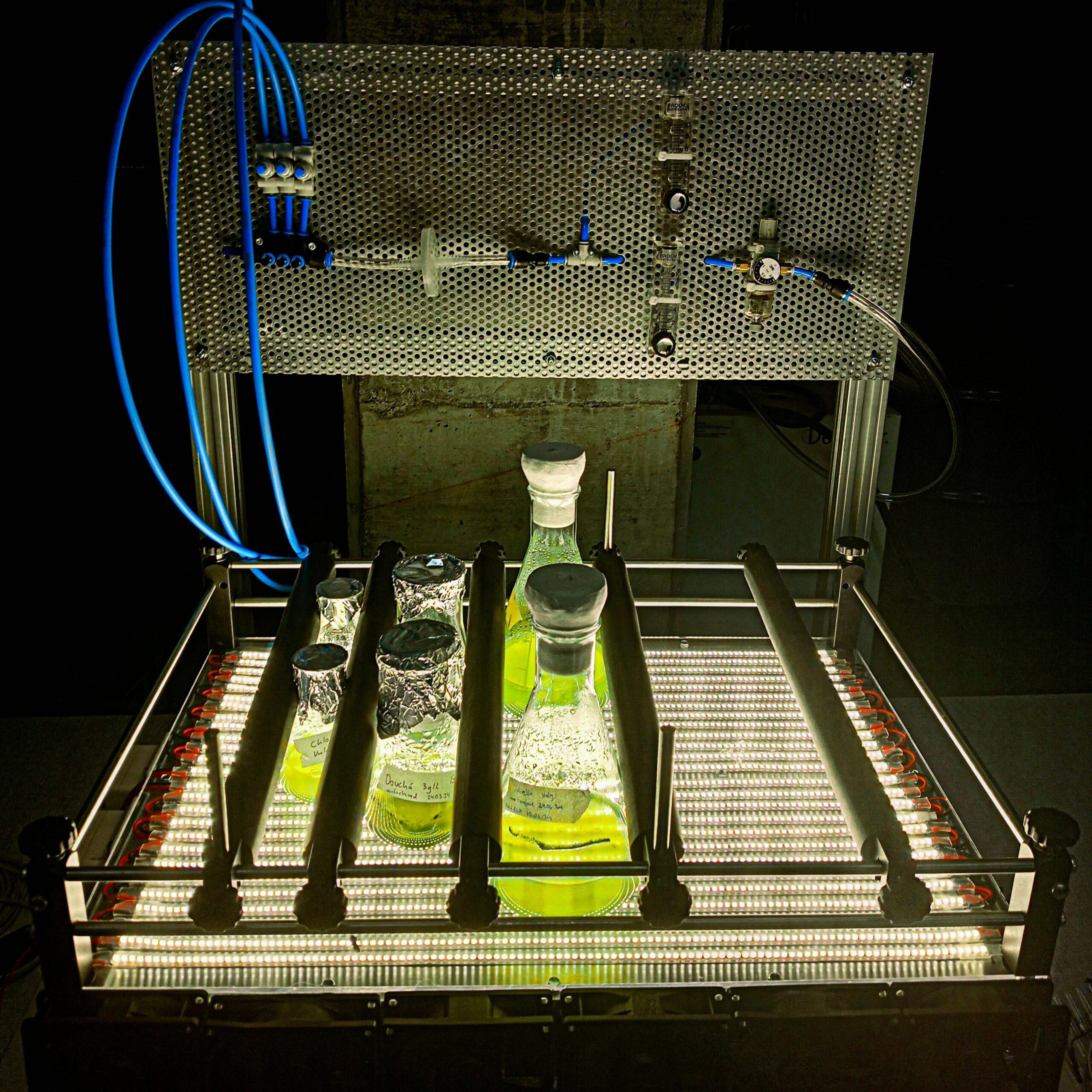

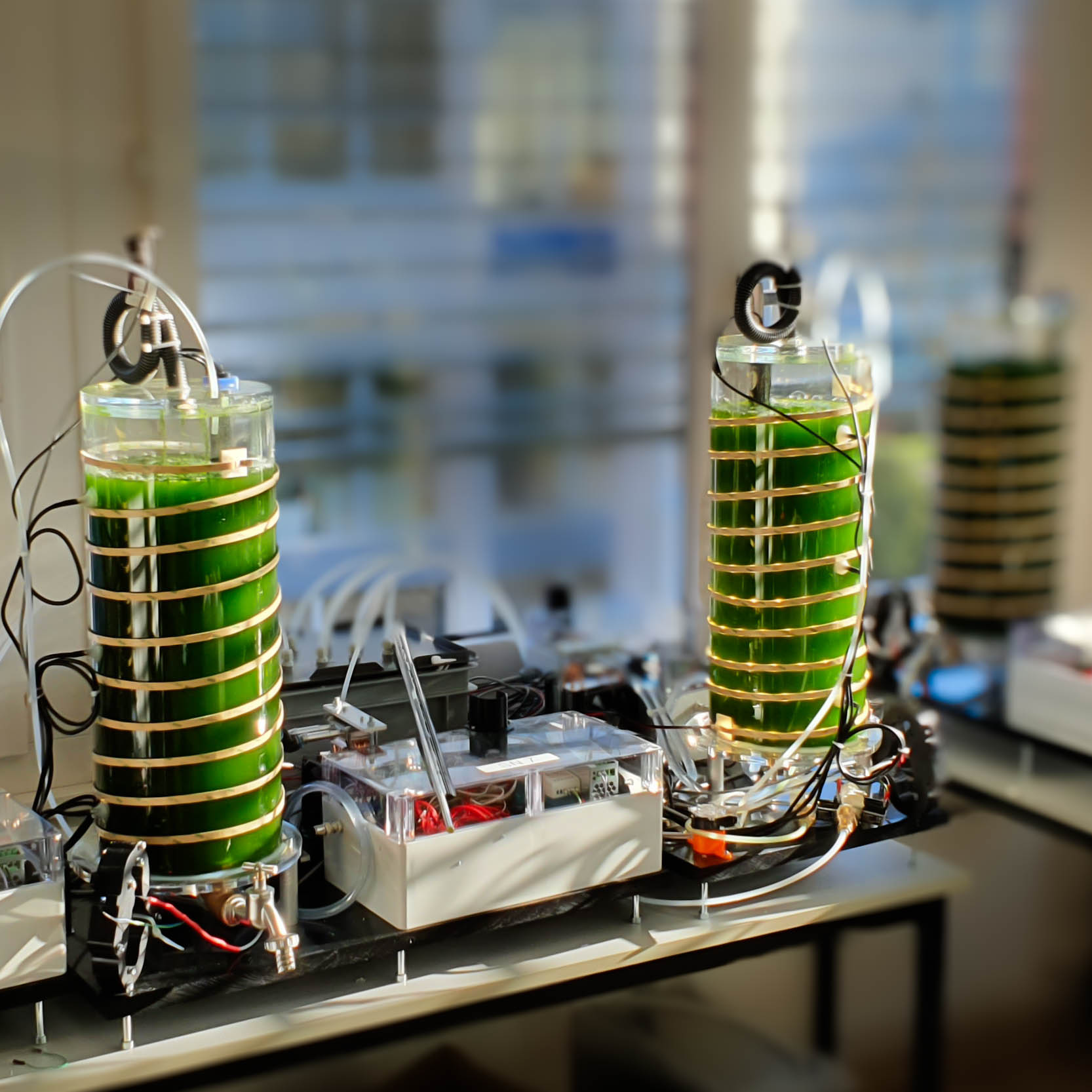

-Experimental investigations & validations at lab scale

Technical Services

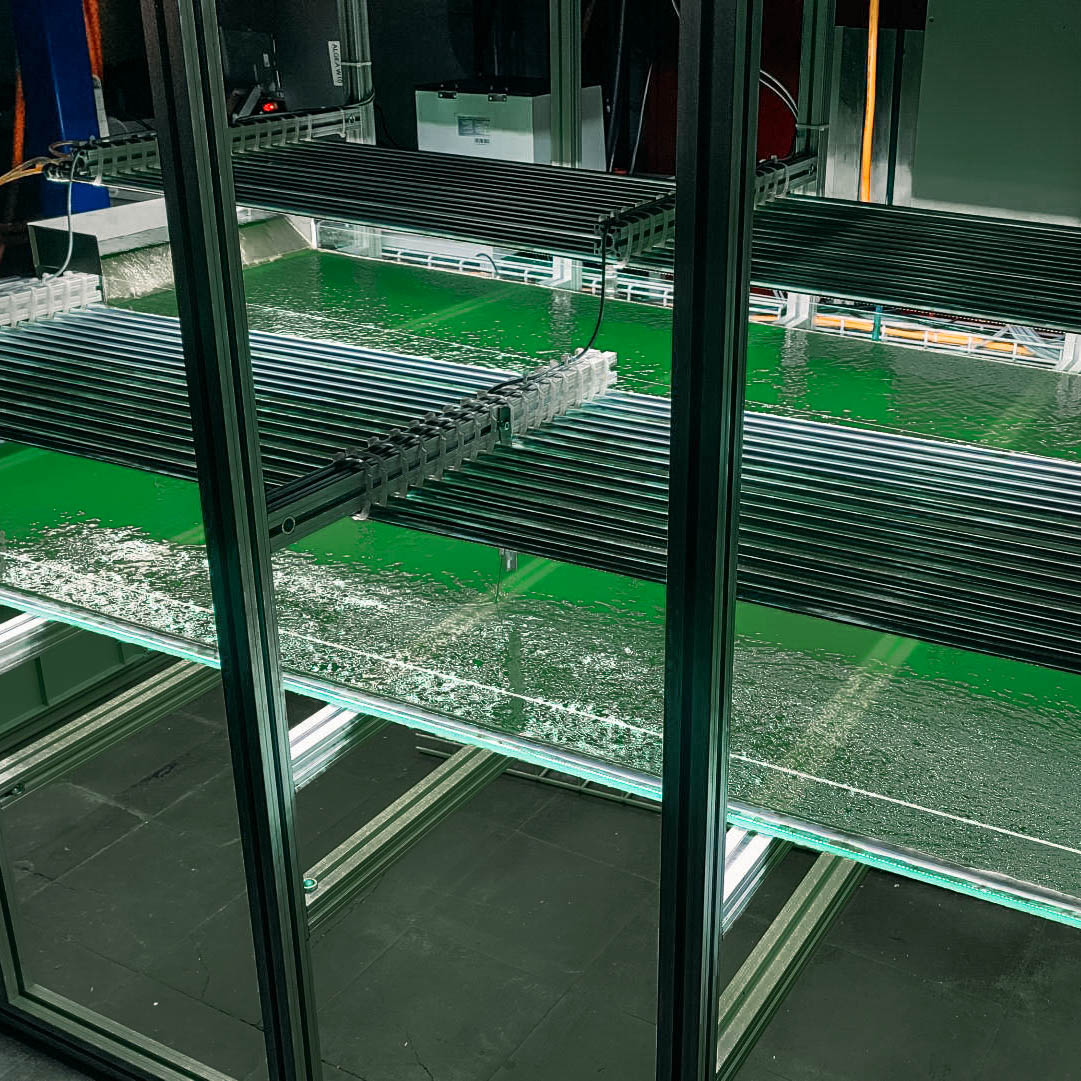

-Bioreactor design & development

-Open and closed systems

-Artificially illuminated and outdoor photobioreactors

-Analytical Services

-Monitoring of key growth parameters

-Real-time biomass tracking

-Sample-based analyses of biomass composition and quality

Biomass production

-Microalgae biomass production

-Inoculum production

-Harvesting & drying techniques

-Different extraction methods

(e.g. oil extraction with soxhlet process)

Our Infrastructure

Frequently Asked Questions

CO2 removal & negative emissions

Why do we need to remove CO2 from the atmosphere?

To mitigate climate change and limit global warming to 1.5°C above pre-industrial levels, we must achieve net zero CO2 emissions by 2050 at the latest. Reducing emissions is the most important and effective measure. But there are some emissions that can’t be avoided or reduced fast enough. To counterbalance these emissions and achieve net zero, we need to remove CO2 from the atmosphere.

Why not just plant more trees?

Planting trees makes perfect sense and is important for mitigating climate change. However, afforestation and reforestation have their limits in terms of their scalable capacity to absorb CO2. They alone are not sufficient to achieve the negative emissions required for net zero.

Why not remove other greenhouse gases such as methane (CH4) or nitrous oxide (N2O)?

The focus is on CO2 removal, as this is the predominant greenhouse gas associated with long-term climate change. Although methane and nitrous oxide are more potent greenhouse gases, they have shorter atmospheric lifetimes than CO2. Reducing these gases is also essential and requires specific strategies, such as improving waste management and reducing agricultural emissions.

How much CO2 can be removed with algae biomass?

For every carbon atom stored in biomass, one molecule of carbon dioxide is removed from the atmosphere. As carbon atoms (C) are much lighter than carbon dioxide (CO2) molecules, 1 kg of carbon stored in biomass is equivalent to removing 3.7 kg of CO2 from the atmosphere. So, if the biomass is 50% carbon, 1 kg of biomass removes about 1.9 kg of CO2 from the atmosphere.

Why the name "Arrhenius"?

In 1896, Svante Arrhenius was one of the first known people to predict global warming caused by human-induced CO2 emissions. More than a century ago, Svante Arrhenius warned of the drastic consequences of burning coal and suspected that the climate could heat up due to excessive levels of CO2 in the atmosphere. We are impressed by his foresight and would like to pay tribute to him.

Algae & biomass storage for CO2 removal

What kind of algae do you use?

We use different microalgae for different applications. For CO2 removal, we use freshwater green microalgae with a high growth rate and a high carbon content to ensure a high CO2 capture rate.

Are the algae toxic or harmful to the environment?

No, the algae are not toxic or harmful to the environment. You can even eat them.

Why don't you just burn the algae?

When the algae are burned, the previously bound CO2 is released again. In this case, the process would only be CO2 neutral, not CO2 negative.

How and where is the algae biomass stored?

The algae biomass can be stored in a wide variety of locations. The most obvious sites are opencast lignite mining areas or underground mines of various types (copper, salt, coal, etc.).